The steel industry, a key player in global infrastructure and economic growth, is experiencing an amazing transformation thanks to AI and big data analytics.

These advanced technologies are changing how things are done throughout the steel production process — from designing materials to manufacturing. They’re also boosting efficiency, sustainability, and innovation, which could reshape the industry’s future. For the latest insights, check out Metalswire.net – Metal Market News.

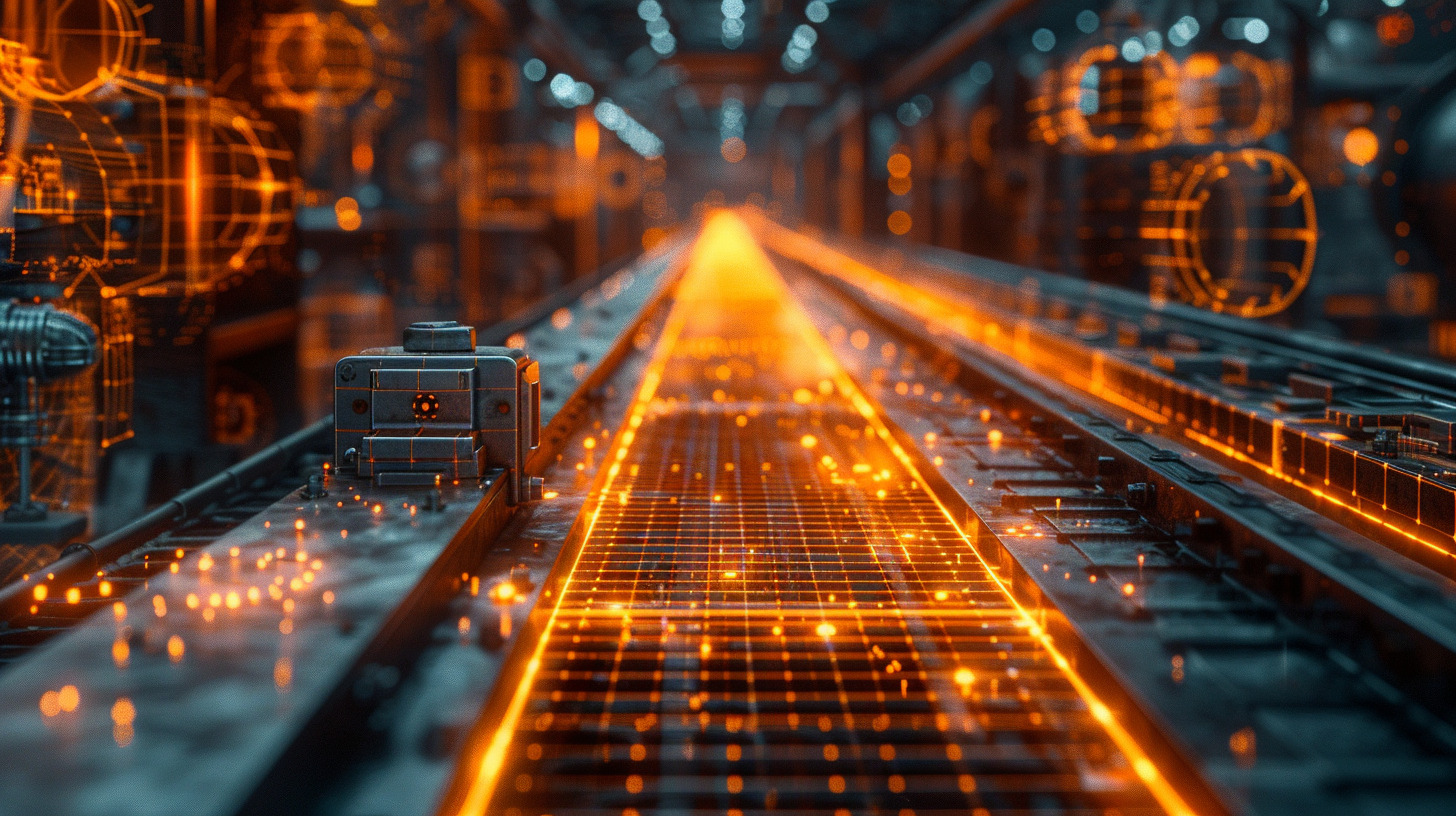

The Power of AI and Big Data

At the cutting edge of AI, machine learning (ML) is shaking up how we design and develop new steel materials. By crunching massive datasets from years of research, production lines, and advanced simulations, ML models can fine-tune steel properties and streamline processes like never before.

This means shorter development cycles, lower costs, and the creation of advanced steel grades tailored to meet the specific needs of various applications, boosting competitiveness and adaptability in the market.

Digital twin technology is another game-changing advancement in this digital shift. By creating virtual replicas of production lines and steel products, manufacturers can accurately simulate and predict how they’ll perform in the real world.

This digital testing playground not only aids better decision-making but also cuts down on material waste, optimizes energy use, and improves overall product quality, leading to more sustainable production practices.

Moreover, ML is key in predicting how steel products will hold up in the real world. By analyzing factors like fatigue, wear, and creep under different conditions, these models help ensure that steel meets the tough requirements of specific applications.

This capability reduces the need for expensive and time-consuming physical testing, boosting both production efficiency and confidence in product design.

Challenges and the Path Forward

Of course, there are challenges on this transformative road. Ensuring consistent high-quality data across different production stages, seamlessly linking information across various systems, and translating complex metallurgical processes into actionable AI insights are critical areas that need ongoing focus.

Furthermore, the industry can greatly benefit from developing a comprehensive platform that supports the entire lifecycle of steel materials — from speedy R&D to production and large-scale implementation, enabling a more collaborative approach.

The Future of Steel

The future of steel manufacturing is smart, driven by a deep integration of advanced technologies with industry expertise. This ongoing revolution will keep redefining the sector, creating a more efficient, competitive, and environmentally friendly industry — essential to the world we’re building.

As the steel industry steps into this new era, it positions itself not only as a leader in technological advancement but also as a guardian of economic and environmental responsibility, vital to building a resilient future.

Conclusion

Integrating AI and big data isn’t just an optional extra but a strategic necessity for the modern steel industry. By tackling these challenges and fully embracing these technologies, the industry can unlock unparalleled levels of efficiency, sustainability, and innovation.

This transformation will have significant implications for global infrastructure, economies, and the responsible use of resources, laying the groundwork for a more sustainable future.